客户专线:025-85561577

Company Profile

Profile of Glaway

Nanjing Glaway Software Co. LTD (Hereafter refer to “Glaway”), was founded in 2010, is the domestic leading solution provider for product life cycle. Its headquarters is located in Nanjing, Jiangsu province. Moreover, it has branches in Shanghai, Beijing, Chengdu and Xi′an.

By adhering to the principle "Intelligent Enterprise Drives China′s Intellectualized Manufacturing", Glaway devotes to helping industrial enterprises create efficient and smooth digital chain of product life cycle by using information technology, and transforming the ways to design, manufacturing, maintenance guarantee as well as operation management of product for promoting enterprises to transform into intelligent enterprises. In this way, the upgrading and transformation, as well as improvement of quality and efficiency for industrial enterprises are realized, which supports the "Chinese Dream" mainly driven by industrial power.

Glaway are specializing in the research and development, consultation service and system integration of relevant software to the overall resolution for intelligent enterprise based on the end-to-end digital chain of product life cycle. Besides, through our own technology and service, we will integrate leading intelligent manufacturing concepts and best practices into information system so that we can provide industrial enterprises with the information solution of intelligent enterprise including intelligent R&D, intelligent production, intelligent supportability, intelligent management and knowledge engineering.

Glaway have a talent team with reasonable skills structure and strong strength. Glaway’s core key bone members have rich theoretical literacy and practical experience of more than 15 years on average in large and complex IT projects, and they have strong ability to lead enterprise IT construction direction and conduct customer demand.

Glaway also has an experienced consulting service team which has the largest number in China PLM industry. It provides customers with specialized and one-stop service from planning, consultation, implementation to operation and maintenance, helping enterprises improve innovation, enhance market competitiveness, improving product quality and shortening the market cycle.

Currently, the industries which partnered with Glaway include aviation, space, shipbuilding, weapon, defense electronics, nuclear, automotive, rail transportation, engineering machinery, energy, high-tech electronics, weight equipment and troops, as well as water and power supply. Besides, the industry famous customers we served are more than 200.

Glaway has formed a long-term partnership with customers by adhering to the service concept of "Value Orientation, Professional Quality, Attentive Service and Perfect Delivery". Furthermore, Glaway is also active behind Chinese important equipment such as C919 large passenger aircraft, CJ-1000A large passenger aircraft engine, new fighter, new carrier rocket, new-type warship, new phased array radar and new high-speed railway.

Company Philosophy

Mission of Company:

Help manufacturing enterprises transform and upgrade by using information technology to boost the "China Dream" mainly driven by industrial power.

Vision of Company:

Become the most leading and influential "Provider for Solutions and Industrial Software of Intelligent Enterprise".

Core Values of Company:

Customer First, Value Innovation, People Oriented, and Teamwork.

Full Life Cycle:

Provides customers with information solutions of product life cycle from product planning, R&D, manufacturing, test and service guarantee.

End to End:

Forms an integrated solution from "3+N" (refers to 3 business processes centering on product life cycle and N management process) end-to-end perspective of business process.

One-stop:

Provides enterprises with one-top information service from IT planning, schematic design, project implementation and system maintenance.

Best Practice:

Refines the best practices of industry through the successful experience of leading enterprises to duplicate and promote them among customers.

Service Concept:

Value Orientation: Taking the realization of customer business value as the starting point and foothold, pay attention to the close integration of advanced concepts and customers′ actual situations and the real implementation.

Professional Quality: Taking the Implementation methodology with rich experience as the action guidance for implementing project, we have created a well-trained and professional consulting service team.

Attentive Service: Infuse the soul of the team with the core value "customer first", and form a long-term partnership with customers.

Perfect Delivery: Ensure the project delivery on schedule and quality during implementation, and be brave to overcome difficulties and challenge under pressure to achieve the project goal.

Company History

~2010: Accumulation of Technology

In 2002, the core team dominated the digital prototype construction of the 14th institute of CETC (China Electronics Technology Group Corporation)

In 2003, the core team dominated the R&D and management platform construction of 14th institute of CETC

In 2008, the core team dominated the construction of integrated supportability platforms of 14th institute of CETC

In 2009, based on the practical IT application of enterprise, gradually enriched software of product innovation and comprehensive integrated supportability management.

2010: Foundation of Company

On December 7, 2010, relying on the development and brand of information construction in CETC, and focusing on the IT business for integrated supportability and R&D management of equipment, Glaway was founded as the situation required.

2011-2012: Business Development

In 2011, the Shanghai branch was founded, which released the first software product of IETM series with proprietary intellectual property rights. Then the company business was expanded to aviation, space-light, national defense electronics, shipping and other industries.

In 2012, Chengdu and Beijing offices were successively founded, with serviced customers over 100. The corporate product line was extended from integrated supportability, R&D management to manufacturing management, while the company business was expanded to automotive and rail transit industries, releasing software products such as integrated development system (IDS) and 3D-MPM.

2013: Strategic Expansion

In 2013, obtained CMMI 3-level certificate, and released series of software products for after-sales service and Maintenance Management System (MRO), when the integrated supportability software system was put into use with the equipment delivered to a customer in a central Asian country. Besides, the company re-positions its strategy to build "the First Chinese Brand in the Whole Life Cycle Information Field of Products" at full blast.

2014-2015: Lay A Solid Foundation

In 2014, we obtained the Quality Management System Certification of GB/T19001-2008/ISO9001:2008, and built an industry-based consulting service team. At that time our solutions were widely applied in the leading units of ten military industrial groups and national key programs.

In 2015, Beijing and Chengdu branches were successively founded. They launched the model-based system engineering (MBSE), manufacturing operation management (MOM), knowledge engineering system (KES), prognostic and health monitoring (PHM) and other solutions.

2016-2018: Overall Arrangement

In 2016, we released the Overall Solution for "Intelligent Enterprise, received the warm response from customers. Then we started the Northwest Strategy to establish a Xi′an branch, completing the national layout.

In 2017, our business was expanded from traditional manufacturing to troops, water and power supply, etc, meanwhile, our journal “Road to An Intelligent Enterprise” was first published, when the number of employees was over 450.

Cooperative Partners

Dassault Systèmes

Dassault Systemes was founded in 1981. As the leader that provides the global customers with 3DEXPERIENCE solution, Dassault Systemes provides enterprises and customers with virtual space to simulate sustainable innovation. Its world-leading solution changed the way to design, produce and support product technically. The collaboration solutions of Dassault Systemes has also promoted social innovation, and expanded the possibility of improving the real world through virtual worlds.

Dassault Systemes has brought value to more than 220,000 customers of different scales from various industry in more than 140 countries.

MSC

MSC software company was founded in 1963, and it is the leader of global multidisciplinary simulation domain. The engineering simulation technology of MSC software company is used to finite element analysis(FEA) of linear and nonlinear, acoustic, fluid-solid coupling, multi-physical field, optimization, durability, multi-body dynamics, and control system simulation. It can truly and accurately predict the performance of industrial products in the real world, thus helping engineering design more innovative products.

IHS Markit

IHS Markit was founded in 1959 and its headquarters is located in London, with 13,000 full-time employees. It is a diversified supplier of global business information service, which provides the world-leading semantic retrieval engine, providing key information, analysis and solutions to all industries and markets that drive economic development around the world.

IGE-XAO

IGE+XAO group was founded in 1986, which is engaged in the design, production, sales and maintenance of a series of CAD(Computer-Aided Design) software. This kind of CAD software is called "electrical CAD". These electrical CAD software are used to help manufacturers design and maintain the electrical parts of all production processes. IGE+XAO has built a whole set of electrical CAD software programs, which can be applied in all industrial fields.

Cortona3D

Cortona3D is a company which was founded in 1989. It is the world-leading enterprise of 3D visual communication and publishing software. Cortona3D software can convert the design data(CAD) into the "visual techniques" used for product maintenance and training. The full three-dimensional display and communication greatly enhanced the effect of enterprise product training, after-sale service and project display.

Introduction of Solution

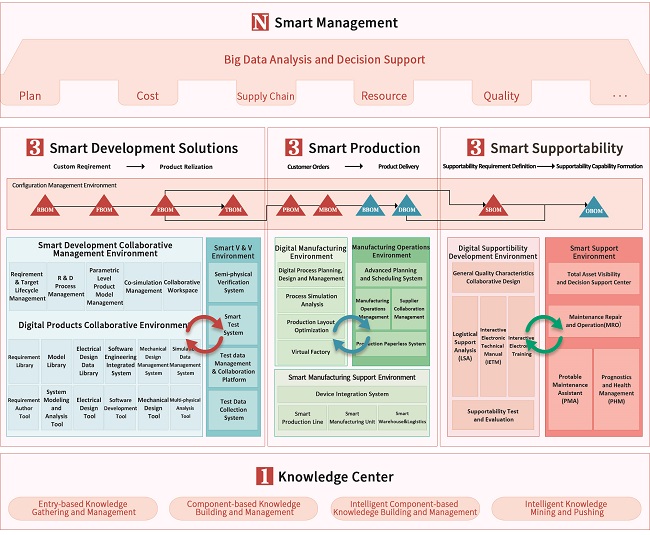

Intelligent Enterprise Solution Diagram

Position of Solutions:

Through providing industrial enterprises with IT solution for intelligent enterprise which includes intelligent R&D, production, supportability, management and knowledge engineering, as well as covers all working content from planning, implementation to operation and maintenance, this solution helps enterprise to create high-efficient and smooth digital chain for product life cycle which reforms the ways to the development design, manufacturing, operation and maintenance as well as management of product, thus significantly enhancing the response speed and flexibility of enterprise, as well as the effective coping capacity of complexity.

Overview of Intelligent Development Solutions

Facing the need of new-type development mode featured with "requirements traction, model penetration, virtual reality verification, positive collaboration, process specification and parallel work", this solution provides the integrated intelligent development solution including whole process trace and tracking, integrated management of project planning process, model-based system engineering, collaborative design and management of digital prototype, as well as multi-specialty collaborative simulation, improving the product innovation ability and market competitiveness of enterprise, as well as shortening the product development cycle and improving product quality.

Overview of Intelligent Production Solutions

In the process of production, this solution connects three digital links: they are product engineeringphysical manufacturing, plan planning and designoperation and maintenance of production system, as well as production planmanufacturing execution of underlying equipment. Through the close integration of IT(information technology) and OT(operation technology), as well as the mapping and closed loop drive between virtual world and physical world, we provide the intelligent production solution including digital process plan and management, manufacturing operation management, outsourcing supply chain management and transparent factory, to realize the new manufacturing mode featured with "Intelligent, Transparent and Distributed".

Overview for Intelligent Supportability Solutions

This solution covers the complete digital design capability of the supportability system ranging from non-functional characteristic collaborative design and comprehensive support analysis to technical publications, spare parts planning and training preparation; and realizes the intelligence of on-site supportability through PHM, spare parts management, equipment maintenance, operation and maintenance management, as well as portable maintenance equipment, to provide the digital, remote and intelligent support for the repair, maintenance and operation of product.

Overview for Intelligent Management Solutions

This solution provides the technical status management of product life cycle, integrated quality management, cost management, big data intelligent analysis and other solutions. Also, it constructs N end-to-end enterprise management processes from up to down. Through the up-down penetration of each control element in the process, this solution realizes top-down and bottom-up state monitoring on the goals layer by layer including strategy, cost, plan and quality, providing the enterprise management with perfect multidimensional decision information covering scientific research, production, guarantee, quality, finance and comprehensive management, thus improving the management efficiency and quality of decision.

Overview for Knowledge Engineering Solutions

Facing the gathering of knowledge resources, and the demand on the whole process of knowledge engineering such as knowledge production, transferring, application and management, this solution provides solutions such as multi-form knowledge mining, knowledge system and knowledge map management, modeling and releasing of knowledge component, knowledge service based on role and scene, knowledge community, knowledge motivation and knowledge portal. In this way, this solution will promote the evolution of "data→information→knowledge-wisdom" in various business fields, and facilitate the creation of knowledge-based enterprise featured with "internalization of external knowledge, externalization of tacit knowledge, modeling of explicit knowledge, organization of personal knowledge and scenario of knowledge application".

Successful Customers

Aerospace

China Academy of Launch Vehicle Technology

Shanghai Academy of Spaceflight Technology

China Aerospace Sanjiang Group Co. LTD

China Academy of Space Technology

Sichuan Academy of Aerospace Technology

China Academy of Space Science, Industry and Defense Technology

China Aerospace Science, Industry and Aviation Technology Research Institute

China Academy of Space Science, Industry and Transport Technology

……

Aviation

Commercial Aircraft Corporation of China Ltd

Chengdu Aircraft Industry (Group) Co. LTD

Chengdu Aircraft Design Institute of China Aviation Industry Corporation

China Aviation Industry Corporation First Aircraft Design and Research Institute

China Aviation Industry Corporation Helicopter Design Institute

Aviation Lifesaving Equipment Co. LTD

Air China Develops Commercial Aero Engine Co. LTD

China Aviation Industry Corporation Aircraft Strength Research Institute

Xi ′an Flight Automatic Control Research Institute of China Aviation Industry Corporation

……

Shipping

Shanghai-east China Shipbuilding (group) Co. LTD

Wenchong Shipping Co. LTD of China-ship Huangpu

Guangzhou Shipyard International

China Design & Research Institute of China Ship and Ocean Engineering

Jiangnan Shipbuilding (Group) Co. LTD

Bohai Shipbuilding Heavy industry Co. LTD

The 701th Research institute of China Shipbuilding Industry Corporation

The 702th Research institute of China Shipbuilding Industry Corporation

The 711th Research institute of China Shipbuilding Industry Corporation

……

National Defense Electronics

China Electronic Technology Group Co. LTD

The Electronic Science Research institute of China Electronics Technology Corporation

The Fourteenth Research institute of China Electronics Technology Corporation

The Twenty-ninth Research institute of China Electronics Technology Corporation

The Tenth Research institute of China Electronics Technology Corporation

The Thirteenth Research institute of China Electronics Technology Corporation

The Thirty-sixth Research institute of China Electronics Technology Corporation

The Thirty-second Research institute of China Electronics Technology Corporation

China Power Technology Avionics Co. LTD

Baojun Electronics Co. LTD of China Power Technology in Yangzhou

Nuclear and Weapon

Research Institute of Computer Application in China Accademy of Engineering Physics

Research Institute of Electronic Engineering in China Academy of Engineering Physics

Laser Fusion Research Center, China Academy of Engineering Physics

China Institute of Atomic Energy

China Nuclear (Tianjin) Machinery Co. LTD

The 25th Research Institute of China North Industries Group

Jiangsu North Huguang Photoelectric Co. LTD

Northern Photoelectric Group Co. LTD

……

Automobile and Railway Transport

China First Automobile Group Co. LTD

Guangzhou Automobile Group Co. LTD

Shanghai Automobile Group Co. LTD

Chongqing Chang’an Automobile Company Limited

Zhuzhou Chi-auto Times Electric Co. LTD

CRRC Qingdao Square Locomotive & Rolling Stock Co. LTD

China-auto Qi Shuyan Locomotive Co. LTD

China-auto Qi Shuyan Locomotive Vehicle Technology Institute Co. LTD

……

Others

China Astronaut Research and Training Center

Jiuquan Base

Micro Satellite Innovation Institute of CAS(Chinese Academy of Sciences)

Hefei Institute of Physical Science, Chinese Academy of Sciences

Tsinghua University

Magna Steyer Automotive Technology (Shanghai) Co. LTD

BORCCI

Shenzhen Institute of Standard Technology

Jiangsu Anchor Glass Co. LTD

……

Project Outcomes

1. In the development of large passenger aircraft C919, we helped customers to implement the collaborative development cross regions and enterprises, as well as configure management platform, to support the parallel work based on a single DMU (digital mockup) for thousands of users globally.

2. In the development of large passenger aircraft engine model CJ-1000A, we helped customers build collaborative development platform, realizing the cooperative development of cross-region and cross-enterprise.

3. In the development of new-generation fighter model, we helped customers to have built a digital platform which supported high-efficient collaborative development across factories and regulated configuration control, realizing smooth transmission of 3D digital chain from design to manufacturing.

4. In the development of a large aerospace model, we helped customers to have built an integrated platform for designing and manufacturing, realizing the collaborative design and manufacturing of six units based on the full three-dimensional digital environment, including three overall and three assembly.

5. In a shipbuilding enterprise, we helped customers to have built s new-generation digital design/process simulation platform, and customized nearly 100 value-added programs, realizing the connection of ship from production design, process to production and construction of digital chain.

6. In a national defense electronics research institute, we helped customers to have built a collaborative development platform based on model. Through the construction of more than ten information sub-items, we realized the connection of all-link digital chain for system engineering, as well as multi-level and multi-professional collaborative development.

7. In a locomotive model, we helped customers to have built an engineering system of full three-dimension which provides the complete capability including 3D digital design, technology, test and DMU management, thus realizing the digital chain from design to manufacture.

8. For a new-type radar, we helped customers to have built projects based on model system engineering, 3D structured digital prototype, 3D process system and lean supportability platform, realizing the smooth transmission of the whole life cycle digital chain for product.

9. In an aircraft manufacturer, we helped customers to have built a digital chain smooth transmission environment of multi-specialty(general assembly, part assembly, machinery process, sheet metal, etc), moving forward an MBE (model-based enterprise) vision.

10. In a shipbuilding enterprise, we helped customers to have constructed an Interactive Electronic Technical Manual (IETM) and technical support system, realizing the precise integrated guarantee of military and local forces.

Our Advantages

Excellent technical team

Gathers the most experienced and senior expert resource.

Makes our good mechanism become the fertile soil for talent growth to ensure that we can provide customers with high-quality services, thus leading the IT direction of customer product life-cycle digitization.

Leading Link-ability of Enterprise Business to Digital Technology

We have the ability to transform, optimize and reconstruct enterprise business process and methods under the of digital technology application.

We have formed the implementation methodology that matches the characteristics of domestic enterprises and ensures the successful implementation of advanced concepts.

Integral Solutions Suite

Through cooperation with foreign leading enterprises and our own accumulation, we have introduced the market a combination of complete integrated solutions that conform to the actual situation of Chinese enterprises and can effectively help the transformation and upgrading of Chinese manufacturing enterprises.

Outstanding Customers Reference

We are in deep strategic cooperation with the advanced enterprises including CETC, Chengdu Flight Aviation Industry, and the 611th branch of Aviation Industry inside the industry to jointly create the excellent projects of enterprise IT. This enables our team to meet customer requirements in zero distance, in order to verify our ideas and products and accumulate rich engineering experience.

Rich Successful Practice

We have many successful cases in the market, and we have gathered rich practical experience through these cases, especially those in planning, implementation and management of large and complex information projects, which is the prominent flag for us to distinguish from other business competitor in the industry.

Contact

Address: F7, Building 53, No.4 Gu ping gang, Gulou district, Nanjing

Telephone:025-85561577

Fax:025-85568791

Zip Code:210013

Address: F3, B7, No.88 Darwin Rd, Pudong, shanghai

Telephone:021-51312200

Fax:021-51312209

Zip Code:201203

Address: Room 515, Yuyou Building, No.16 Yard, Meiliyuan Middle Road, Zhanghua South Road, Haidian District, Beijing

Telephone:010-88192148

Fax:010-88192146

Zip Code:100089

Address: Room 1501, Building#B, Jinsha Wanrui Center, No.1 Sichuan Golden Road, Qingyang District, Chengdu

Telephone:028-64044398

Fax:028-64044398

Zip Code:610074

Address: Room 1207, Building A, Mole centre, No.34, Fenghui South Road, Xi’an

Telephone:029-88855942

Fax:029-88855942

Zip Code:710065

官方微博

官方微博 官方微信

官方微信